Metallurgical know-how

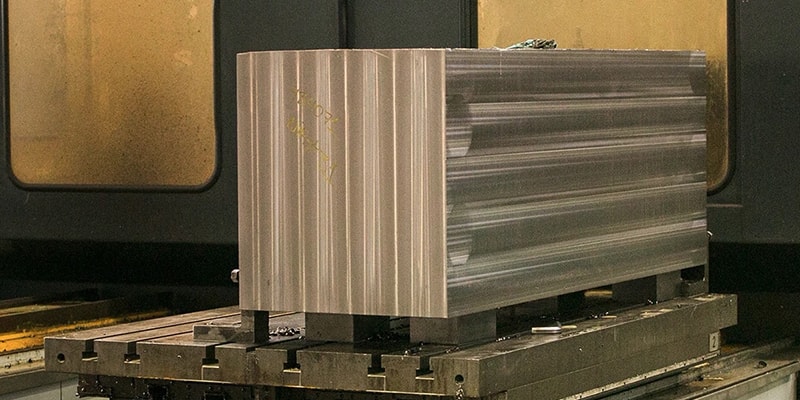

Our forged blocks and plates guarantee great levels of resistance and ductility because of their high-quality materials and attributes achieved in the steel forging process, making them a better choice than castings—especially for applications that need greater strength or longer life.

MATERIAL |

RANGELength up to 315 in |

WEIGHT RANGEUp to 77,000 lb |

BENEFITS

-

Our process guarantees a reduction area ratio of a minimum of 3 to 1, which allows us to ensure optimal block and plate soundness.

-

Compared with castings or flat-rolled products, the forging process provides the directional grain flow and metallurgical microstructure needed to improve mechanical properties such as impact and tensile strength.

-

At FRISA, we are a one-stop forging shop offering value-added services such as heat treatment, machining, and testing to provide you with the best solution.